This is our communicative tool that explains our corporate values and identity, of which ESG themes are an integral part, even outside the corporate walls.

Company

Experience and constant excellence

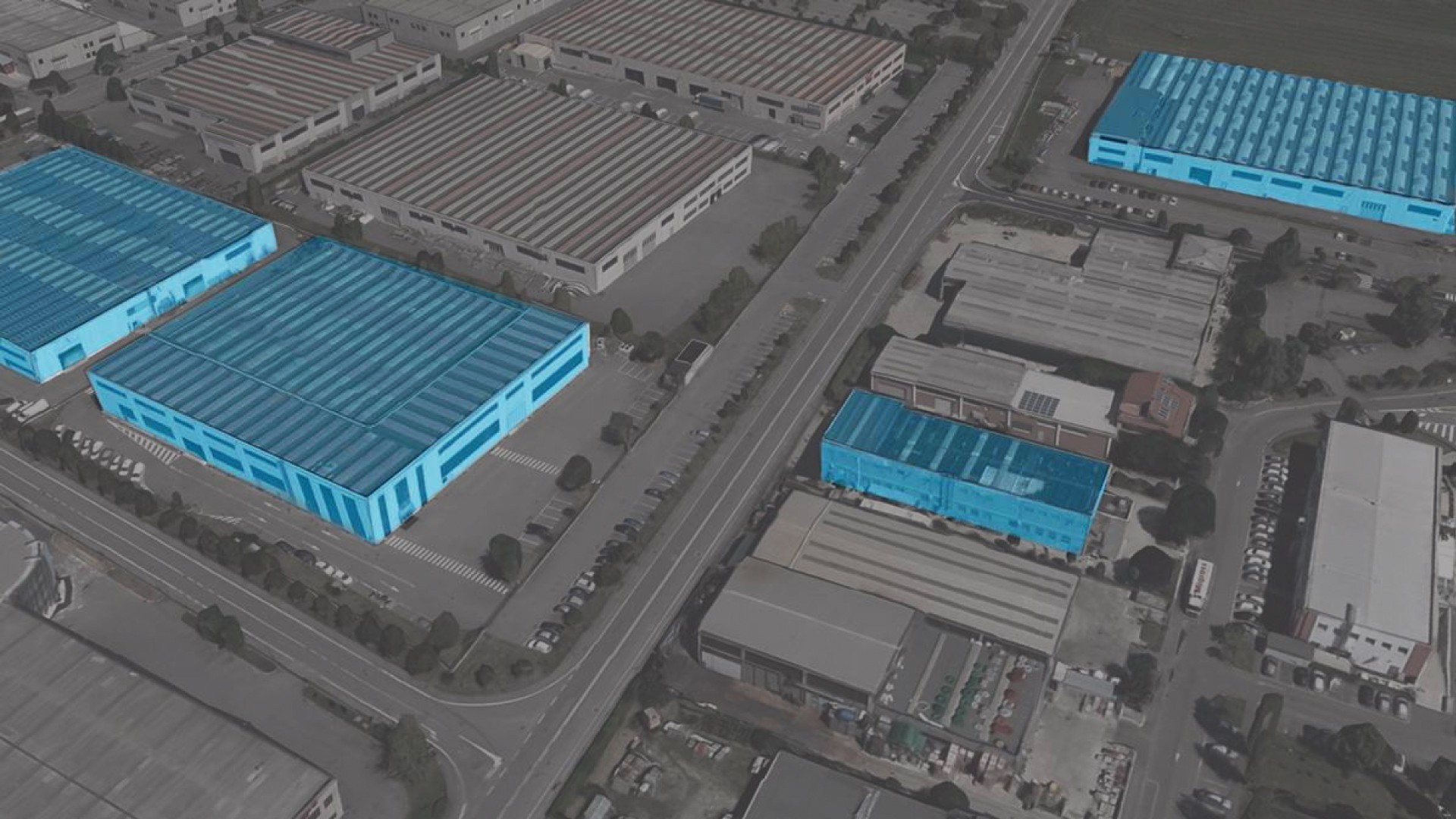

All the fundamental phases of design and production are carried out internally in Bergamo headquarters; further sales offices are located in Germany, Spain and in the United States. From 1977 on, the company continued growing; at today, it counts over 400 employees dedicated to product excellence.

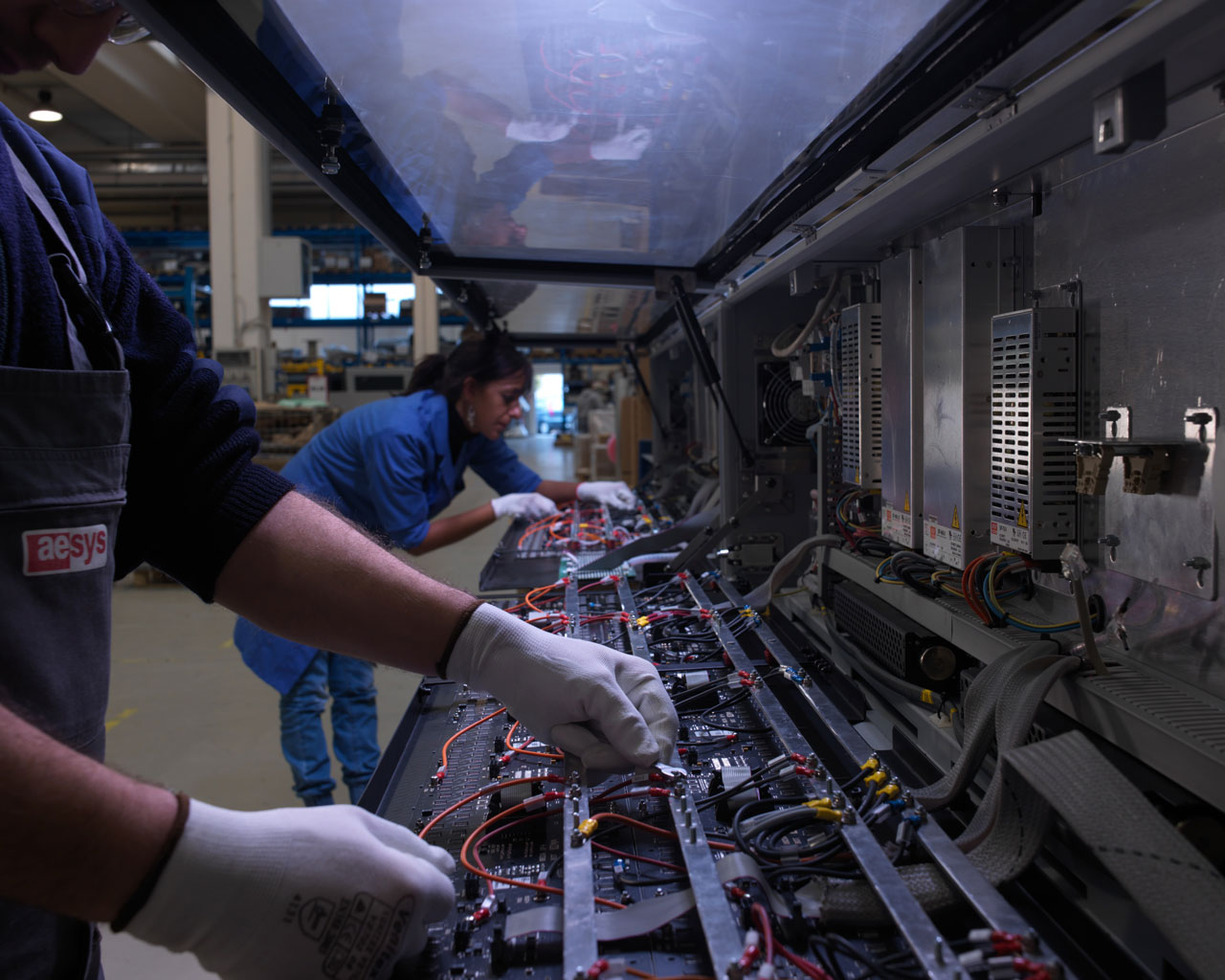

Production 100% Made in Italy

In Aesys, quality is above all. Work is based on efficient internal procedures to deliver flawless results to customers.

Sustainability system

The ambition to do well and always better is part of our essence: the voluntary drafting of the Sustainability Report has meant representing and formalizing the path of maturation started over the years, which has led us today to be able to fully include awareness on ESG themes in our way of being.

Roadmap and constant commitment

At Aesys, we are committed to constantly improving our contribution to sustainable development: we have reflected on our specific corporate context and on the more general operating sector to identify a series of relevant SDGs in which Aesys may implement active policies.

The sustainability and integration committee is at your service

Organization, management and control models

For a proper and transparent company management, Aesys has its own and exclusive Model pursuant to Legislative Decree 231/2001

Mission and vision at a glance

Aesys will always be a solid, qualified, healthy and sustainable reference point for shareholders and its products help customers and partners in grwoing their business. The support with technical and commercial experience were the base of a global expansion.

The aim is to set the standards of excellence in products and customer service; travellers and citizens across the World, as end users, enjoy, appreciate and recognize Aesys products. Our direct customers rely on this feature and expect us to constantly improve the serice quality.

Certified products

For those who consider excellence their goal, like Aesys, it is fundamental to focus on quality at every stage of the productive process.

Behind the flexibility of our products and our technological solutions there is a 360 degree quality.

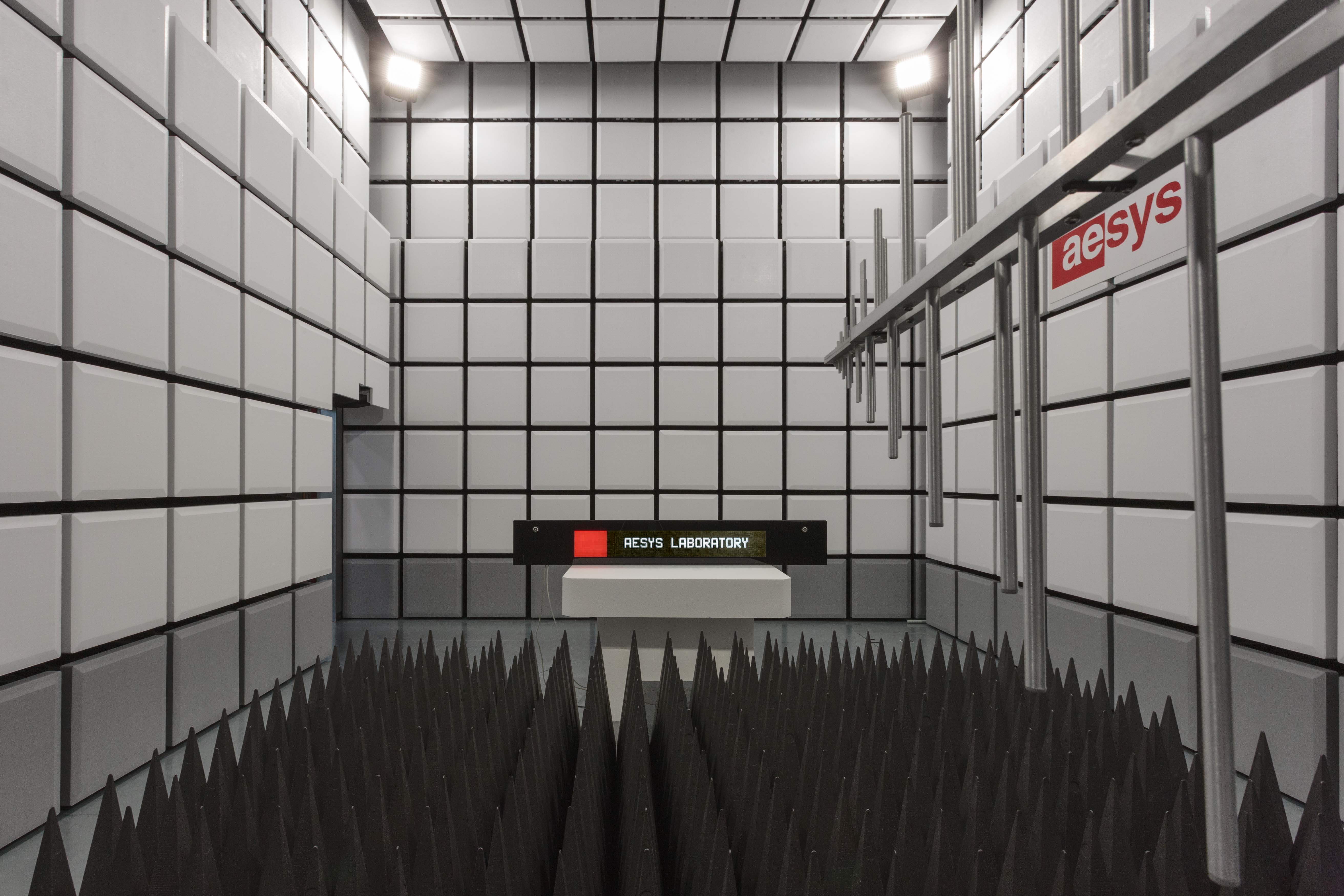

Discover our laboratory

Equipped with cutting-edge and state-of-the-art instruments, including a large semi-anechoic chamber, the Measurement Laboratory reflects the constant search for improvement. Aesys carries out a wide series of tests right from the early stages of prototyping, involving designers in validating results, to follow innovative solutions or proceed towards new paths. The tests continue on samples taken from the production lines, in close contact with the Quality Control.

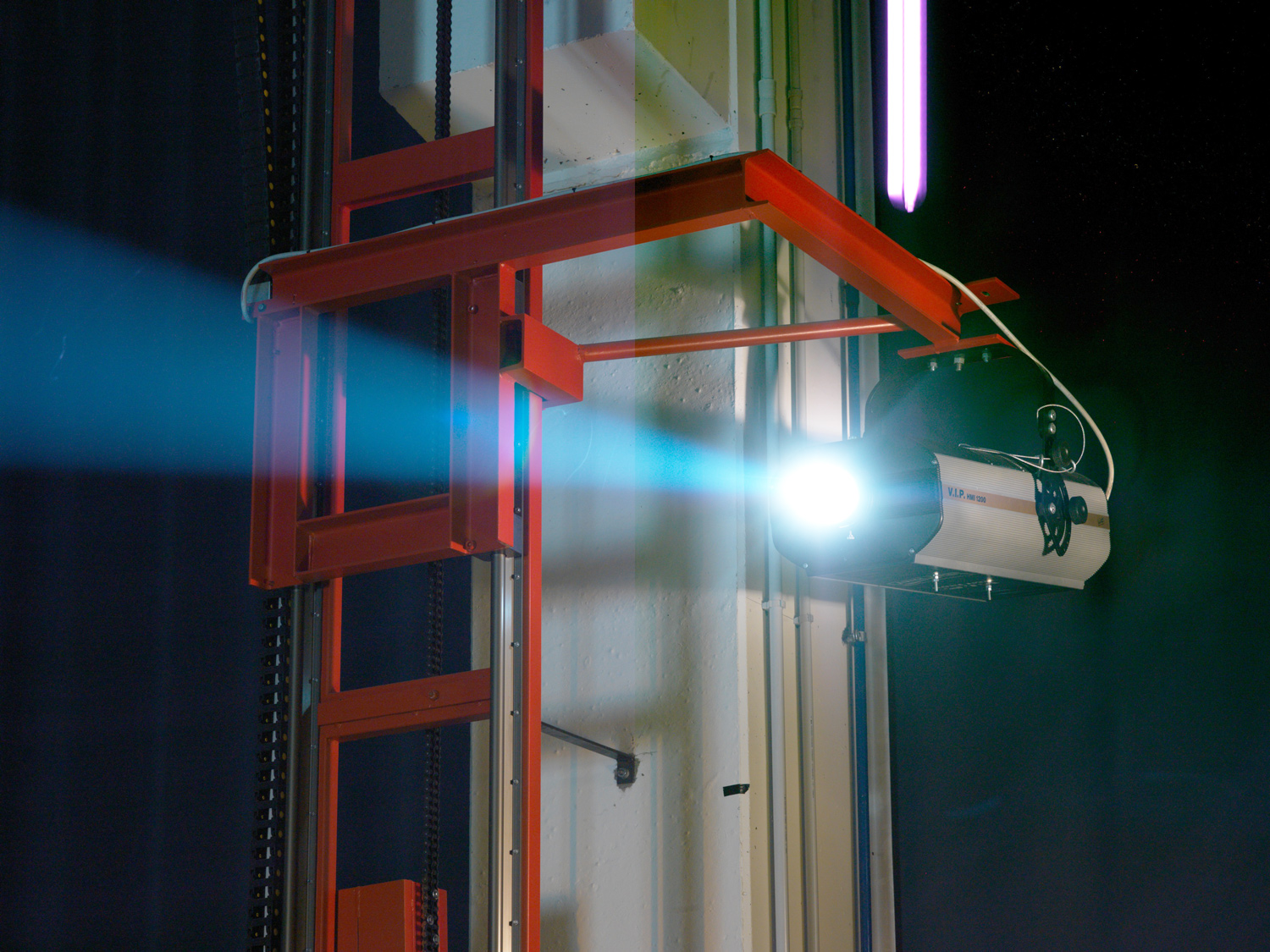

Optical measurements

Measuring the optical features of the panels to determine the readability of the information displayed. Tests include:

Color

Brightness

Viewing angle

Luminance Ratio

Luminous Intensity Uniformity

Environmental and Mechanical Measures

Conducting environmental testing certifies the ability of the device to withstand adverse environment conditions. Certain tests will also verify the mechanical strength. They include:

Dry Heat

Damp Heat Cycling

Change of Temperature

Cold

Solar Radiation

Impact Test

Water Penetration Test

Dust Penetration Test

Electromagnetic Compatibility

Many electronical devices transmit and receive electromagnetic waves which may impact normal operation of that device or surrounding devices. To eliminate or reduce this interference to an acceptable level and to ensure proper operation, the verification of electromagnetic compatibility (EMC) has become a prerequisite for electronic devices sale in many countries around the world. The tests detect both electromagnetic energy emission and immunity.

Electrical Measurements

Electrical safety standards define the requirements that all electrical equipment has to meet to protect the user and prevent damages to the device. Causes of risk include direct electrical contact, indirect electrical contact, current overload, short-circuits, and power surges. The tests simulate phenomena that can be observed in low voltage power distribution systems, telecommunication lines, or data lines. They ensure that the device continues to function after being exposed to artificially generated transient noise. The regulations provide different acceptable levels for each product type being tested. The tests include: